Quality Assurance and Quality Control in Construction

At Saral Nirmanika, we know the importance of quality construction and that is why in each and every construction project, it is the topmost priority for us. QA/QC standards ensure that a project is completed successfully and safely while adhering to the set regulations. Both these components are important facets in avoiding defects and legal framings, along with guaranteeing the longevity and soundness of the construction project.

What is Quality Assurance and Quality Control?

Quality Assurance (QA) is a preventive approach aimed at ensuring that no defects are allowed to occur in the construction process. Through a clear plan and standards in the execution process, QA is able to check on each phase of construction and make sure it meets the required qualities. QC, on the other hand, is the examination of the end product for any flaws and the subsequent rectification of these faults. While both are crucial for success, they differ in approach: QA is all about the avoidance of problems while QC is about the identification and elimination of problems.

Quality Assurance and Quality Control are two interrelated terms that can seem very similar but are actually quite distinct.

The Quality Assurance and Quality Control difference is that the former is broader in scope, proactive in approach, and more oriented toward the future. QA confirms that processes are set in a way to avoid error, thus laying the groundwork for quality. Quality Control, on the other hand, involves the examination and evaluation of the completed work for flaws that occurred at the construction phase. QA and QC have significant roles in guaranteeing the quality, safety, and successful implementation of construction projects.

Why Quality Assurance and Quality Control Matter?

When it comes to construction, it is critical to uphold quality to ensure that the structure is safe and will last for quite some time. When there is no proper implementation of QA/QC, it leads to a number of problems including time loss, quantity survey and billing, and health risks for the personnel involved in the projintegral:

Our Approach to Quality Assurance and Quality Control

The quality that is enforced at Saral Nirmanika follows a sequential pattern to make sure that all aspects of a project are completed to the highest standards. To prevent any hitches, we ensure that there is both Quality Assurance and Quality Control from the initial stages up to the end of construction.

Quality Control Plans

Our first step is the creation of a Quality Control Plan, which details how each part of the project will be audited and controlled for quality. In this plan, there is the implementation of certain inspection and testing tasks on the materials and work done for conformity to the required standards.

Technical Specifications

It is often crucial to understand that every project has its specifications. It contains technical specifications detailing the material to be used, tools and techniques required, and procedures to be followed in the construction process. These are the foundational aspects of both QA and QC to guarantee that the work is done as required and in the best interest of the project.

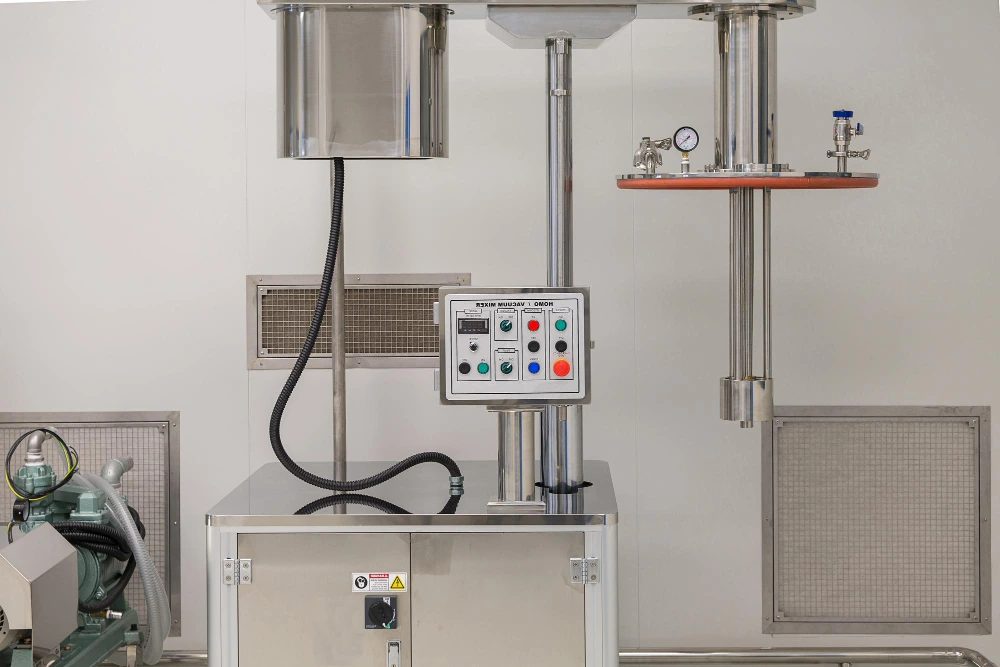

On-Site Establishment of Quality Laboratories

In the case of activities for which first-level testing and analysis are necessary, we create on-site quality laboratories. These facilities enable the quick and effective testing of materials with the aim of excluding those that do not meet the laid down requirements in construction. It is beneficial to have a lab in-house because it does not cause delays and the quality of work is not compromised.

Implementation of Quality Plans at the Site

The crux of the matter however is how the Quality Control Plan is implemented. Like most organizations, we create a structure to ensure that all team members adhere to quality standards by inspecting, testing, and verifying all completed work based on the quality standards of the project. Such an innovative strategy ensures that the project is delivered to the best quality and safe standards.

Key Components of Quality Assurance and Quality Control

Here’s a quick overview of the key components that make up a successful QA/QC system:

|

Quality Control Plans |

Documents the procedures for testing and inspecting materials and work throughout the project. |

| Technical Specifications |

Provides detailed material, equipment, and method requirements, ensuring consistency and quality. |

| Quality Control Laboratories |

On-site labs for real-time testing and analysis of materials, reducing delays. |

| On-Site Execution |

Ensures the implementation of quality control plans, with regular inspections and verifications. |

At Saral Nirmanika, we are committed to providing quality at every step of the construction process. By focusing on Quality Assurance and Quality Control, we ensure that your project is completed to the highest standards, on time, and within budget. Our expertise in developing comprehensive Quality Control Plans, setting technical specifications, and establishing on-site labs makes us a trusted partner in construction.

Let us help you achieve a successful, high-quality construction project every time.